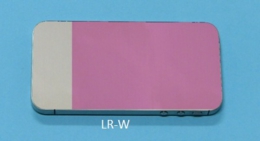

LR-W

White Chemical Conversion Coating for Magnesium Products

The chemical conversion coating on magnesium products, which usually

Is brown, can be much whiter by our LR-W treatment and the white LR-W

coating conceals uneven dark lines and spots due to uneven flow of the

alloyed metals on the surface of the products.

The white LR-W coating makes painted colors brighter and reduces layers

of under-coating required.

coating conceals uneven dark lines and spots due to uneven flow of the

alloyed metals on the surface of the products.

The white LR-W coating makes painted colors brighter and reduces layers

of under-coating required.

Distinguishing Characteristics of the LR-W Treatment

● Conceals uneven tint of the cast surface

● Makes painted colors brighter

● Reduces layers of the under- or base-coating

● Most suitable to paint coating of light and bright colors

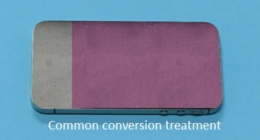

Difference in appearance of the painted color

The below photos show digital image of painted clear pink on the LR-W coating, our standard non-chromate coating,

ANC treatment, and a common conversion coating in the market. As the LR-W coating is much whiter than others,

painted pink is brighter and clearer.

ANC treatment, and a common conversion coating in the market. As the LR-W coating is much whiter than others,

painted pink is brighter and clearer.

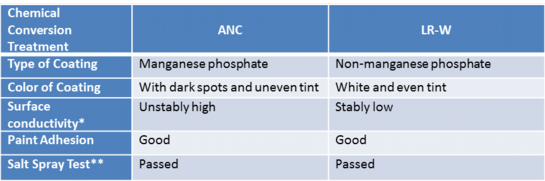

*) Surface conductivity: By MCP tester of Mitsubishi Chemical Analytec

**) Salt spray test: JIS Z2371 in spraying for 8 hours and keep at room temperature for 16 hours.