CB processing

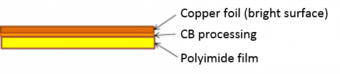

Glue-less bonding of not-treated brightglossy copper foil surface (without roughening) and the polyimide film

Flexible Copper Clad Laminate (FCCL) is conventionally formed by polyimide film as base film with copper foil laminated by adhesive agent or thermoplastic polyimide as adhesive component.

Using CB processing technology, CB treated metal foil is laminated to the base film, then it can be heat-laminated or heat-pressed to be composite material without using any adhesive agent; that is to say adhesive agent such as thermoplastic polyimide is no more necessary (glue-less) once CB processing is used.

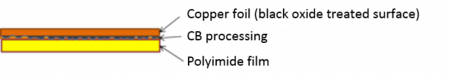

The conventional bonding required etching or black oxide treatment (roughening treatment) on the copper foil surface to give it anchor effect in order to strengthen adhesiveness. However, a conductor’s surface is preferred to be plane in order to reduce transmission loss, because with a high frequency band the signals get concentrated on the conductor’s surface (into approximately 2μm with 1GHz) by skin effect. But, due to roughening treatment, the copper foil surface becomes uneven with irregularities of a few μm. The signals, then, will be transmitted along this uneven surface, which increases the transmission distance that results in transmission loss increase.

With CB processing technology, films can be bonded to copper foil without any adhesive agent, so that there is no need to rough the surface; that is to say the surface resistance is very small, reducing signal transmission loss considerably. In addition, with CB processing technology much higher adhesive strength can be obtained than using conventional adhesive agent, so that the flexible printed circuits can be greatly bent.

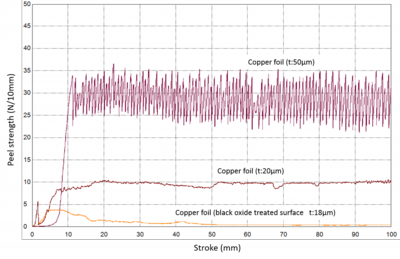

As indicated below, the peel strength of the polyimide film laminated by CB processing with bright copper foil without roughening treatment is shown. As the condition details are confident at the moment, please contact us directly for more information.

Copper foil: 20μm (bright surface), 50μm (bright surface)

Polyimide film: 50μm

※Bonding data of bright copper foil surface and LCP film click