CB processing

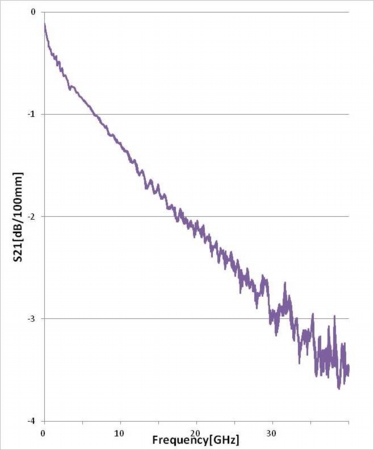

Decrease in transmission loss on Flexible Printed Circuits (FPC) material made of LCP and copper foil which LCP is laminated with not-treated bright copper foil without adhesive.

Nowadays, applications for mobile communication devices are more diversified and network speed is becoming faster. Acceleration of CPU’s operation speed and transmission speed in information communication now require high-speed signal transmission even for FPC used in small electronic devices.

Material selection is crucial in addition to better structural design in order to realize excellent high-frequency characteristics.

In order to achieve low transmission loss and delay,

1) We have chosen Liquid Crystal Polymer (LCP), a material characterized by low dielectric constant and low dielectric loss (tanδ).

2) The copper foil must not be roughened in order to avoid losses due to skin effect.

3) It should be laminated without using adhesive agent.

By having performed these points, excellent characteristics were obtained to avoid transmission loss as shown in the following figure.

※Click here to see the peel test results.

Ground – Signal – Ground (GSG) test

LCP-Copper foil transmission loss data

Characteristic impedance Z0 = 50Ω

Rolled copper foil thickness: 18μm

LCP thickness: 100μm

Cover lay: None

Measurement device: made by Agilent Technologies Inc.

Network analyzer E8363B

Measurement environment: Temperature 20 – 25 ℃

Humidity 40 – 60% RH

By applying CB processing, the smoothness of copper foil surface has been maintained as the copper foil is chemically bonded to LCP without adhesive and surface-roughening by etching or black oxide treatment, by which we have achieved reduction in transmission loss caused by skin effect.